|

FTC Rocket Construction

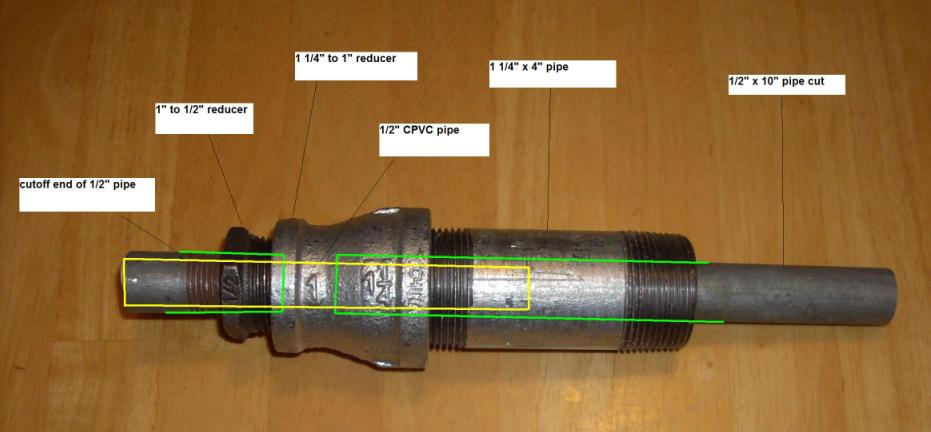

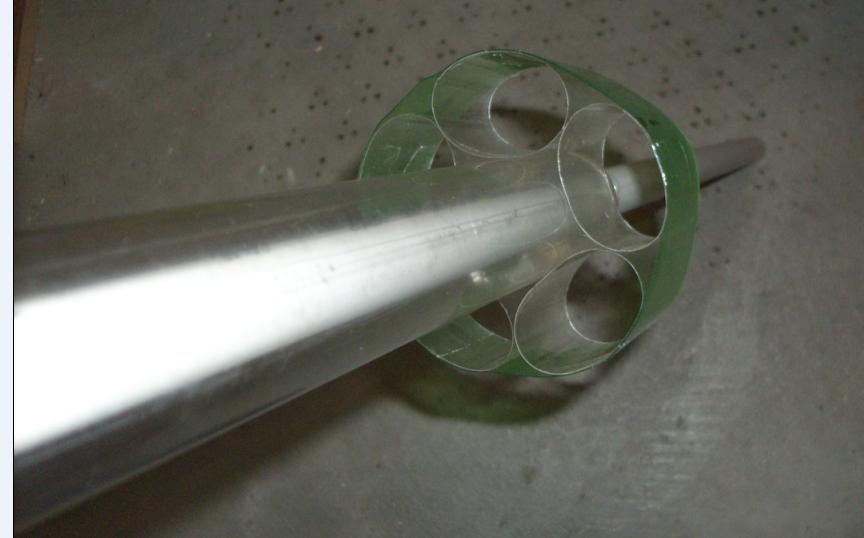

I made a special mold to make shrink soda bottles into a custom end for FTC rockets. The 4" section of 1 1/4" galvanized

pipe is the key to the correct diameter. The threaded end is also a key to having the inside diameter of the shrunken

soda bottle taper down to the correct size for fitting over the end of the rocket tube. The 1/2" pipe that was cut is held

together with 1/2" CPVC pipe. I used a hammer to pound in the pipe within a pipe on one end, screwed in the other cut

off pipe and then hammered the sticking out CPVC into the smaller cut off end. A picture is worth a thousand words here.

Here are some other examples of the FTC construction:

http://www.orgsites.com/va/bristolwaterrockets/_pgg6.php3

http://users.hubwest.com/gordo/bottleneck.html

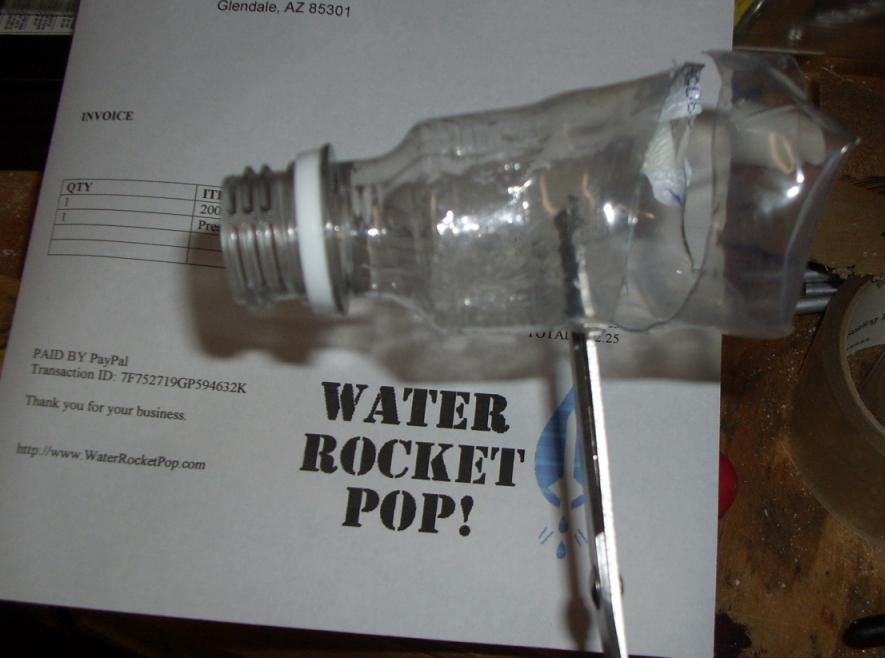

Cut a 16 or 20 oz or 1 liter bottle so that the end plastic goes past the threads of the 1 1/4" pipe.

Slide on the soda bottle end as far as it will go.

Protect your hand with a good glove. Protect the threads of the soda bottle by covering with the glove.

Hold over heat (I bought a heat gun just for this) and rotate to shrink the soda bottle down to a tight fit.

The tight fit should be all over the threads or just a little less.

When done shrinking, unscrew the soda bottle to remove from mold.

Trim the soda bottle with scisors but leave enough to easily slide over the rocket body.

Sand the inside of the custom molded end. Sand the outside of the rocket body. Clean parts with alcohol. Spread glue

on rocket body and on custom molded end to ensure even coverate. Slide the to parts together. You can easily align

the two ends of the rocket by inserting a section of 1/2" PVC pipe.

For fins I used 5 (five) sections of FTC cut about 3" long. And one section of 2 liter soda bottle. The 2 liter

section compresses and holds the FTC sections togther. I used pieces of tape to hold the FTC sections to the 2 liter

section so they don't slide around. Then the fin assemply slides onto the rocket and a little tape holds it in place

Stay tuned for parachute recovery. But for now, I just cap the nose of the rocket. A foam football cut to fit over the rocket nose serves

well as a bounce recovery.

Flight video coming soon.

|